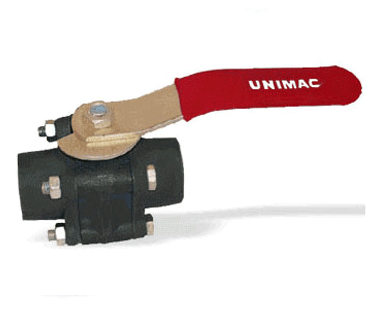

Industrial ball valves are a fundamental component of the fluid control systems. The main function of these valves is to precisely and dependably direct the flow of liquids, gasses, and other substances. They provide rapid and precise control of the flow path by using a round ball with a rotary hole in the center.

The capacity of industrial ball valves to handle high-pressure, high-temperature, and corrosive fluids makes them highly respected for their robustness and simplicity. This makes them great for difficult applications like power generation, chemical processing, oil and gas, and water treatment.

As the leading manufacturer of industrial ball valves, we are skilled at offering premium valves made to satisfy the exacting requirements of numerous industries. In order to provide our clients with trusted fluid control solutions for their vital operations, our ball valves are designed with efficiency, stability, and efficiency in mind. Our industrial ball valves have been built to provide superior performance, save downtime, and enhance operational safety, no mater your industry—oil and gas, chemical manufacture, water treatment, or power generation.

We offer high-performance valves made for the high standards of several industries, including water treatment, chemical extraction, and oil and gas. Our ball valves provide accurate control over the flow of gases, liquids, and slurries, guaranteeing dependable, secure, and reliable operations in any number of applications. We take happiness in providing a wide selection of valves that are appropriate for high-pressure, a high temperature, and chemically opposing settings. These valves are constructed from sturdy materials involving carbon steel, stainless steel, and corrosive alloys.

Since they offer a dependable means of halting reverse flow and ensuring that the system operates effectively and securely, ball check valves are essential components of energy and fluid systems. By the sliding of a round ball toward a seat, these valves turn the flow to stop it as the pressure reduces.

Ball valves for check valves are frequently found in pipelines, pumps, and flow protection systems where only one direction of flow is important. Because of their dependability as well as easy design, ball check valves are widely utilized across different industries.

As a ball valve manufacturer, we recognize the need of valve system customization. To meet the unique needs of various sectors, we offer a variety of products, including sanitary valves, 2-way and 3-way ball valves, and customized options.

Whether you need manual, electric, as well mechanical valves, we have the expertise and capacity to provide the best solutions for your fluid control requirements. Our team works directly with clients to provide tailored solutions that the improve output, minimize functional time off, and improve success.

1) Oil and Gas Industry

➢ Flow Control:Valves are used in pipelines to control the flow of crude oil, natural gas, and refined products.

➢ Pressure Regulation:Critical for maintaining safe pressure levels in pipelines and storage tanks.

➢ Shutoff Valves: Used in emergency shutdown systems to quickly stop the flow in case of a leak or rupture.

2) Chemical and Petrochemical Industry

➢ Chemical Processing:Valves are used to regulate the flow of chemicals in reactors, pipelines, and other processing equipment.

➢ Temperature and Pressure Control:They help manage temperature and pressure in chemical processes, ensuring that operations are safe and efficient.

➢ Isolation and Safety:Valves prevent hazardous reactions and contain pressure spikes that could lead to accidents.

3) Water and Wastewater Treatment

➢ Flow Regulation:Used to control water flow in treatment plants and distribution systems

➢ Shutoff Valves:Allow for isolation of parts of the system for maintenance or repair.

➢ Backflow Prevention:Specific valves prevent contaminated water from flowing back into clean water systems.

4) Power Generation

➢ Steam and Gas Control: Valves regulate the flow of steam and gas in power plants to ensure optimal energy production.

➢ Cooling Systems:Valves control the flow of cooling water to prevent overheating in reactors or turbines.

➢ Safety Shutdown:Emergency shutdown valves are used to safely stop flow in critical situations, protecting equipment and personnel.

Efficiency & Productivity: By providing automated and real-time data insights, Unimac's control systems optimize processes. This aids companies by boosting overall production, decreasing downtime, and improving the administration of resources.

Customization: The system's great degree of adaptability enables it to meet the specific needs of several areas, including manufacturing, laundry, and any other area need exact control.

User-Friendly Interface:Users need not have advanced technical knowledge for using and changing the Unimac Control System thanks to its easy-to-use user interface.

Advanced Technology: It incorporates the latest technology that enables improved performance, like remote tracking and testing skills, to help teams stay ahead of any issues.

Owned & Powered by : #1 Vinayak InfoSoft - SEO Company Ahmedabad || Disclaimer || Sitemap